"Road Trip!" It's the quintessential rallying cry of college life.

A dozen engineering students at The Ohio State University's Center for Automotive Research (CAR) in Columbus are gearing up for a road trip of their own. These students are too diligent for one of those rowdy frat-house misadventures in movies like Animal House, but they do plan to do some serious speeding. They don't break rules, but they do push limits – specifically, the limit of how fast a green vehicle can go.

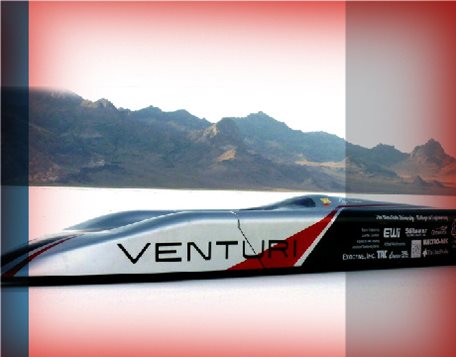

Meet the team behind the Venturi Buckeye Bullet (VBB), the world's fastest electric car. These mechanical and electrical engineers in training have designed and built their sleek 38-foot missile on wheels for one reason: to break 400 mph. With two blistering passes down the fastest track on Earth, Utah's sunbaked Bonneville Salt Flats, the Venturi Buckeye Bullet will attempt a feat no other electric car – and only a handful of internal combustion cars – has yet achieved.

|

| The team behind the Venturi Buckeye Bullet (VBB). Image: Ohio State University / CAR |

Even if they fall short of the 400 mph mark, the team is likely to break the world land speed record (LSR) for electric cars of 307 mph. But this battery-powered blitz is about more than the record books. After all, the standing electric LSR is theirs to beat. The Venturi Buckeye Bullet project connects students with a chance to call the shots in a complex, high-profile project that requires inter-professional teamwork with something at stake that's far more important than race times: the life of their driver. The complexity of the car's custom-designed power train, fuel source, and surface structure is intended to boost its performance, but the added technical challenges will also give its student engineers an unparalleled collaborative experience in applied, out-of-the-box thinking.

The Magic Bullets

The Venturi Buckeye Bullet debuting at this fall's Bonneville Nationals Speedweek is actually the third and most advanced competitor to race for Ohio State under that name over the past decade. "The three fastest electric cars ever built by anyone have all been built here at Ohio State by our students," says faculty advisor and CAR director Giorgio Rizzoni.

Each prior VBB version has made its own mark on the land speed landscape. Beginning with a 2004 U.S. national record of 315 mph notched by the C-cell powered VBB 1, the CAR operation soon hit the big time – two back-to-back world records sanctioned by the Federation Internationale de l'Automobile (FIA). The second-generation Bullet, powered by a hydrogen/fuel cell combination, ran its flying mile at 302 mph at the 2009 Bonneville nationals. That record fell the following year to the VBB2.5 in a second FIA-sanctioned record speed of 307 mph using lithium-ion battery power. Along with the new record, the team acquired vital performance data on systems under consideration for the third-generation car.

The design team for the current model is still working through some of the final engineering challenges, but members are optimistic their Bullet will hit the 400-mph target. Reflecting those ambitions, their approach will integrate lessons learned from its champion predecessors into a total redesign for stability at higher speeds. A critical new feature is the novel motor design, developed in collaboration with Monaco-based sports car company Venturi Automobiles – the project sponsor and collaborator that the puts the "V" in VBB. The all-new racer will compete as the Venturi Buckeye Bullet 3.

Bullet List

What does it take to push an electric car past 400 mph without breaking apart or cart-wheeling across the desert? The design of the vehicle involved structural design, packaging optimization, the design of front and rear independent suspension and brake systems, the design of the body shape using computational fluid dynamics and wind tunnel testing, and dynamic and aerodynamic stability analysis, Rizzoni explains. Here's a quick look at some of the key design and performance of the VBB3.

- Power/Transmission: The increased power demands of a 400-mph run influenced the decision to distribute the output among four motors, with a target output of 1,800 horsepower, supplied via dual transmissions to all four wheels. "The final motor design called for a three-phase AC induction machine with four poles, 0–10,500 rev/min operating speed range, and a maximum mechanical over-speed of 12,000 rpm," he says.

- Aerodynamics: The team's aerodynamics specialists have one of the biggest challenges – anticipating the increased effects of drag at significantly higher speeds than they've dealt with in the past. Designers call cars like the VBB "streamliners" because of their long aerodynamic shape and enclosed wheels. The VBB's sleek-as-a-needle shell is made of carbon fiber panels to cut through drag. A single stout tailfin helps achieve stability at high speeds under the unpredictable wind conditions at Bonneville.

- Materials: The lightweight design is built around a chromoly space frame chassis wrapped in a Nomex-cored carbon fiber body. The driver safety cell encased in the middle of the vehicle is made from a modified IndyCar.

- Electrical system: The heart of the VBB3 is its battery system, comprising two large banks of prismatic iron nanophosphate lithium-ion batteries – some 2,000 in all – configured to create a 900 VDC bus and a 20 kW/h capacity. The pouch-type power cells fit snuggly together within modular containers. This approach delivers more juice in less space than traditional cylindrical battery arrays. A modified inverter is used to convert the batteries' DC power into appropriate AC currents and voltages.

- Driver: All this technological glitz would be for naught without some good old-fashioned human skill and courage. Roger Schroer, a development driver at Transportation Research Corporation's (TRC, East Liberty, OH) nearby automotive proving ground, has piloted Buckeye Bullets to two previous world records.

The Bullet's True Aim

World records are great, but whether the VBB3 succeeds or fails at Bonneville is secondary to the value of the hands-on experience these future engineers are gaining in the design process, Rizzoni says. The Buckeye Bullet may be built for speed, but its true purpose is to put aspiring mechanical and electrical engineers to an ultimate test of collaborative, creative problem-solving. And by shattering a few world records in the process, he says, it raises public awareness of the potential of electric cars as practical, even fun, alternatives for the future.

.jpg)

0 comments:

Post a Comment